Innovations.

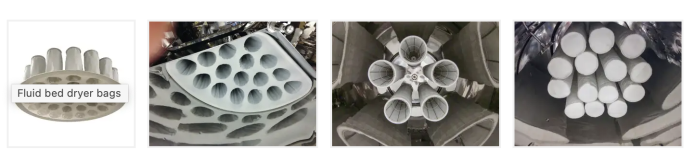

WOKU – High-Performance Filtration Solutions

REXPAC has partnered with a leading German manufacturer specializing in high-quality filters for the pharmaceuticaland chemical industries.

Our filter elements are produced using identical materials and specifications as the original equipment manufacturers (OEMs), eliminating the need for re-validation.

Cost savings of 30–50% compared to traditional OEM pricing—without compromising on quality or performance.

Noxilizer to provide NOX FLEXTM Rapid Biodecontamination units for Weiler Engineering, Inc.’s

ASEP-TECH® Blow/Fill/Seal Systems – providing a new solution for pharmaceutical and related industries.

Companies announce exclusive supply agreement for Blow/Fill/Seal market.

Noxilizer, Inc., the company advancing a room temperature, NO2-based sterilization process for life science manufacturers, and Weiler Engineering, Inc., a leader in the

global Blow/Fill/Seal equipment market, announced today an exclusive supply agreement. Noxilizer will provide the NOX FLEXTM Rapid Biodecontamination units for new Weiler Engineering, Inc. ASEP-TECH®

Blow/Fill/Seal systems.

Today, Blow/Fill/Seal (B/F/S) systems use steam or sanitization to decontaminate portions of the machine.

The NOX FLEXTM provides a sterilization and depyrogenation process in a patent- pending application for the shroud area of new Weiler ASEP-TECH® B/F/S machines